Replacing outdated inverters can significantly boost the yield of a PV power plant and rectify equipment failures. Jörn Carstensen of Germany-based greentech looks at the technical, financial and logistical considerations involved in a successful inverter repowering project.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

The replacement of inverters is not only important in the case of defects, but it can also significantly increase the yield of the plant and extend a solar farm’s lifetime beyond the feed-in-tariff (FiT) period. To be successful, the repowering project should be well planned and closely monitored. Inverters are the heart of the PV plant.

They have interfaces to all relevant areas of the electrical system and make the electricity produced by the solar modules usable for the grid at the correct specification. In addition, they provide information about yield data or possible faults. However, over time technical weaknesses can occur which will lead to a reduction in the performance of the system, increasing repair costs and more frequent maintenance intervals. In recent years, many of the components for PV systems have not only become cheaper but also more efficient and capable of generating a yield increase of between 3% and 5% with the same capacity. These developments may justify an investment in new inverter models even if the existing ones are still running without issues.

Successful repowering requires careful engineering and design

Every inverter replacement requires close coordination with the responsible grid operator. If necessary, a plant certificate or the appropriate protection and control systems must be retrofitted. Furthermore, inverter repowering during the FiT or any other compensation period is a good opportunity to prepare the system for continued operation afterward. In many cases, the additional yield compensates for the repowering costs incurred – this is especially true for older plants that have only a short remaining term under the incentive scheme but receive high tariffs. Projects can thus pay for themselves after only two to three years. In addition, manufacturer guarantees and warranties for the new components are renewed.

Example 1: Reverse use of a DC combiner box (DCCB)

In this example, the main DC cables of the module generator led centrally to the inverter station. However, the only available inverter model compatible with the original inverter power and voltage level of the modules did not have a central DC input, but only several string inputs. In consultation with the inverter manufacturer, a DCCB was designed that divides the main DC cable into several individual strings according to the inverter’s specifications. This meant an additional component and installation effort but prevented a significantly more costly rewiring of the entire system.

AC integration

On the AC side, it also makes sense to build on the current infrastructure and connect the inverters to the existing low-voltage (LV) main distribution and AC cable system. Since the power of the new inverters usually does not exceed that of the existing ones, cable cross-sections and fuses are usually compatible. The reconstruction of the LVAC system is not only time-consuming and expensive, but additional risks would also arise due to the opening of new construction areas at the plant.

Different voltage levels of the inverters may also have to be considered on the AC side. Today, the nominal voltage is predominantly 400 or 800 volts. When replacing an inverter, the applied AC voltage must be checked and, if necessary, adjusted via a tap changer on the transformer.

Plant communication system

To ensure the performance of the plant, a functioning plant monitoring system is indispensable. Data loggers connected to the generation units and plant sensors collect corresponding data and forward it to a monitoring portal. However, different models of inverters have different data protocols. In the case of a partial repowering, the data logger must therefore be able to process and send the protocols of both the old and the new inverters. In the extension, it is then necessary to include the new components in the monitoring software and reconfigure alarms if necessary.

However, it is not only data from the components themselves that must be collected, stored and forwarded – it is crucial that the inverters react to the active power control of the grid operator or PPA provider and are also able to implement specifications with regard to reactive power. In the event of a replacement, this control system must be rebuilt, set up and tested. Here, it is important to coordinate closely with the responsible grid operator.

Mechanical installation

Changing from old to new string inverters in the field is usually not an issue from a mechanical point of view. The regular installation requirements and structural aspects need to be considered.

Central inverters and other technical components are often installed in fixed stations on the plant site and are protected from external influences. Dismantled inverters must be disposed of properly – recycling proceeds can certainly be achieved here.

Before installing the new models, the available space must be checked as manufacturers have different installation requirements, for example regarding the distance between the units and the walls of the station. Depending on the situation, additional DC or AC combiner boxes may have to be accommodated and the cables routed accordingly so that they comply with the specified bending radius.

Consider existing infrastructure when choosing new inverters

New inverters should be as compatible as possible with the existing infrastructure – otherwise, the costs quickly rise to uneconomical levels. It often makes sense to replace central inverters with large string inverters or to replace many old small string inverters with a few newer, large ones. However, this also means that all interfaces to other system components, such as cables or fuses, must be validated and adapted if necessary.

DC integration

Older systems often have a lower system voltage on the generator side than newer systems. Depending on the age of the system, new inverters must therefore also be able to operate at that lower voltage level. This alone can limit the selection of suitable products. In older systems, central inverters with complex wiring and cabling of the module strings up to the generator connection are often installed, which are barely compatible with newer models. However, the structure and the wiring of the generator side are usually not changed when replacing the inverter. This is not only for cost reasons alone. The original DC dimensioning should not be exceeded, otherwise there is a risk that the tariff/ROC payments will be withdrawn.

Example 2: Using the outside wall of an inverter station

When replacing old inverters with new string inverters, according to the manufacturer’s specification, more space was needed than was available in the station. As a solution, the outside of the station was also used. Cables were led through the wall into the cable basement of the station. Since the area was not fenced, the outside use required not only weather protection but also additional access protection. As this changed the external appearance of the facility, this solution was agreed with the local authorities beforehand.

Nevertheless, optimisations of the system can be achieved through the process of repowering if, for example, module strings are connected directly on the new inverters and previously used combiner boxes are omitted. This reduces possible sources of error and future maintenance requirements.

It can be more difficult when converting from central inverters to string inverters as the DC main cables cannot always be connected directly to voltage-compatible devices. In cases such as this, an individual solution must be found.

Business planning

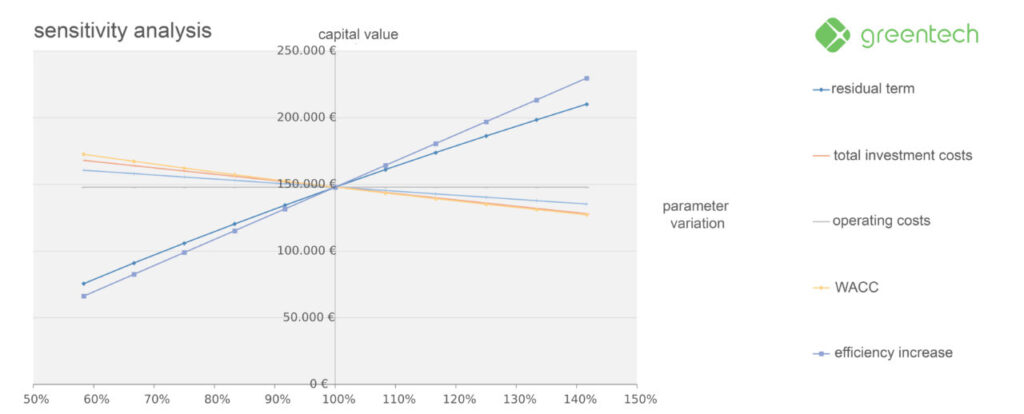

For the investor, solid planning also includes a transparent overview of the economic potential of an inverter repowering. Here, reliable key figures within the framework of a profitability and sensitivity analysis help.

It does not only show the repowering costs and benefits – it also provides the impact of possible deviations. Is an investment still worthwhile if, instead of the assumed 3% increase in yield, only 2.5% is achieved? Or if the costs of the project turn out to be 10% higher than calculated?

Implementation

The implementation of every construction project must be closely monitored. In the case of inverter repowering, this begins with checking the design documents for completeness and plausibility. At least three visits for quality control should take place on site. At the start of construction, the engineering, the installation schedule and any special points should be discussed.

The risk assessment and method statement should be verified and signed by all parties involved. In a second meeting during the construction phase, the focus lies on the implementation quality. The design documents are compared with the situation on site – if conditions differ, points may have to be decided instantly. Finally, the work needs to be accepted. In addition to checking the construction work and compliance with the manufacturer’s specifications, this also includes functional testing of generation and communication as well as checking the technical documentation and measurement protocols.

Follow-up

To verify that the planned benefit of a repowering project really happens, a comprehensive evaluation is carried out after about one year of operation. If all inverters are replaced, this is not so easy, as a suitable reference is missing, and fluctuating irradiation and temperature conditions make an analysis difficult. However, innovative evaluation methods such as a power curve analysis are suitable for this and can identify also smaller deviations reliably and by this provide an objective basis for evaluating the measure. After the completion of the repowering, it is time to discuss the maintenance scope of the new inverters with the operator as well as a possible adjustment of the O&M fee.

Authors

Jörn Carstensen joined greentech in 2014 as sales manager and has played a key role in shaping the company’s continuous growth path. In addition to entering the UK market, he built up the engineering and technical advisory division. Today, as managing director, Jörn is responsible not only for business development but also for the operational areas of plant operations, field service as well as engineering and technical advisory. Prior to greentech, Jörn worked for the Conergy Group from 2006 to 2014, including in the areas of post-merger integration as well as corporate and business development. greentech is an integrated photovoltaic specialist, with a range of services covering project development, design, construction and operational management of photovoltaic power plants in selected European markets. In addition, greentech offers services in the fields of quality assurance, yield maximisation, financing and electricity marketing.